The relationship between the sealing effect and roughness of oil seals

When we design oil seals, we have relatively high requirements for the surfaces that match them. There must be no scratches, gaps, processing marks, etc. to prevent leakage. According to some standards, the roughness requirements for the shaft surface are generally Ra=0.2~0.8μm; Rz=1~4μm; Rmax=6.3μm, and the roughness requirements for the housing hole surface are generally Ra=1.6~6.3μm, Rz=10~20μm, Rmax=25μm.

Since the oil seal and the shaft are dynamic seals, the requirements are higher than those for static seals. Today we will talk about two more important topics in the relationship between sealing effect and roughness that people usually don't pay attention to.

1. Is the roughness of the mating surface as low as possible?

We all know that high roughness is definitely not good for sealing, but is the roughness as low as possible? Actually, it is not. Putting aside the difficulty of processing, when the surface is too smooth, the lack of those tiny "pits" to store lubricants will increase the friction and wear between the oil seal mating surfaces.

According to relevant research, Ra=0.1~0.3μm is the best range for dynamic oil seals. When the roughness value Ra is less than 0.025μm, the wear will increase significantly. However, in general, it is time-consuming and costly to achieve such a low roughness, so it is not necessary. Here I mainly want to tell you that many times things are too much or too little.

2. Does the sealing effect of the same roughness value have the same effect?

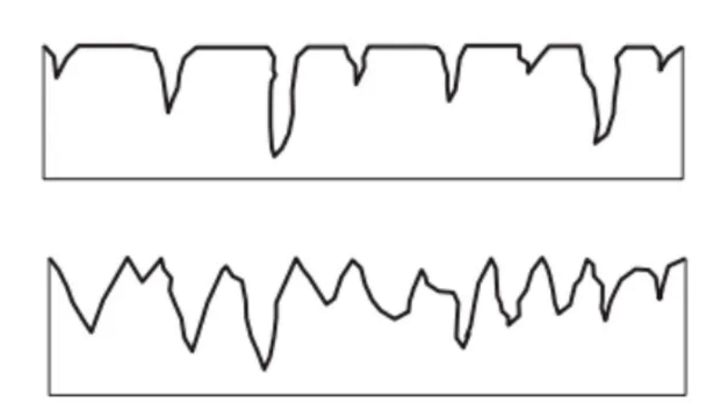

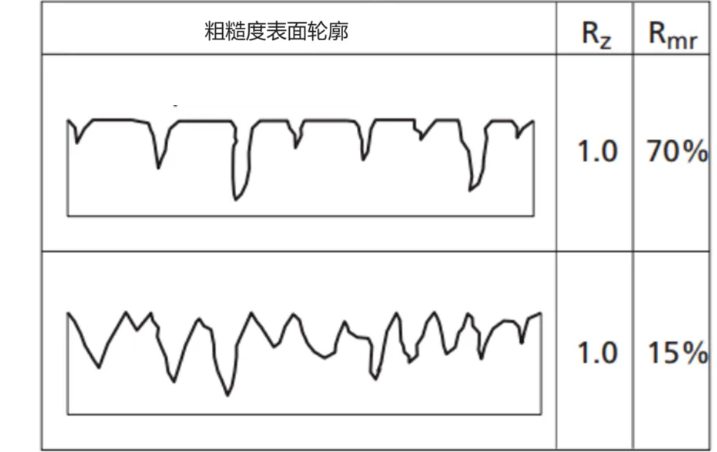

Let's take a look at the following two microscopic images of roughness. Their roughness values are both Rz=1μm. Do you think they have the same sealing effect?

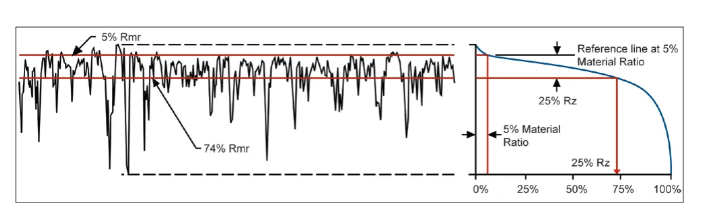

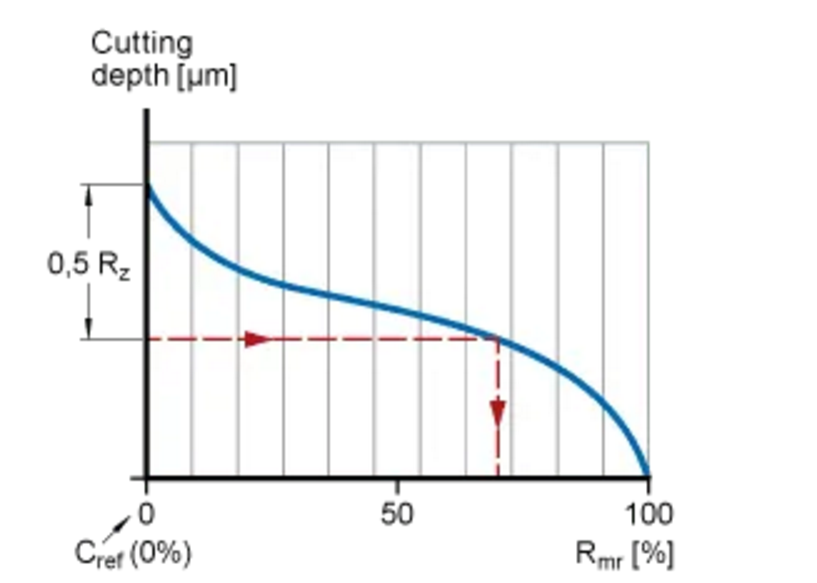

Actually, no, there is still a big difference between the two. In order to evaluate this difference, we introduce a more commonly used evaluation parameter here, that is, the material proportion Rmr, which is usually expressed as a curve (also known as the Abbott-Firestone curve). It describes the ratio of the effective material area to the total area on any cut surface within the evaluation length range, from the peak to the bottom of the valley.

Related links:Maximize Yamaha SMT Nozzle Efficiency: Tips & Troubleshooting

The commonly used method to evaluate the effect of roughness on sealing is: take the horizontal line at the corresponding point of 5% material ratio as the reference zero line, and take the corresponding measured material ratio at the Rz value position of 25% downward. According to different sealing materials, the Rmr value should be between 45%-90% for the most reasonable

Of course, there are other evaluation methods, such as the material ratio at the 0.5Rz position recommended on the SKF website, but the starting point is not the 5% above, but 0%.

Let's go back to the example of the two roughness diagrams of Rz=1μm that we gave you earlier.

The Rmr of the top one is 70%, and the one below is only 15%. Under the same roughness value, 70% Rmr can provide better sealing. On the one hand, it does not have too many grooves on the surface, which reduces the wear on the sealing surface and possible leakage paths; on the other hand, it also has some ideal recess depths, which can retain lubrication in a small enough volume, and provide a lubricating film between the seal and the mating surface, thereby reducing friction and seal wear.

With the development of technology, different processing methods may be used to obtain the same roughness value, but the final sealing effect may not be the same. This also requires everyone to pay attention.more